Mild Steel to 1” Thick

Stainless and Aluminum to ½” Thick

AR400/500 and Wear Plate to 1” Thick

Parts are Cut the Same Day in Most Cases

Accurate & High-Quality Cuts

Our 60 x 120-inch fiber laser is very accurate and produces high-quality cuts.

Cutting 3/16-inch hot-rolled HRPO steel.

Cutting 16-inch gauge galvanized steel

Cutting 1-inch steel

Cutting 1/4-inch aluminum

We Stock Common Materials

Our inventory of sheet stock enables us to respond rapidly:

- Hot Rolled Steel

- Cold Rolled Steel

- Galvanized Steel

- Stainless Steel

- Aluminum

How Do You Get

Your Parts Cut?

- Email us your Print, Sketch or CAD File — We respond promptly

- We work with most 2-D and 3-D CAD formats.

- If you do not have a CAD file, we will create the file as a courtesy for simple parts.

- If you have questions or are new to this, please CALL US (440) 214-9018. We often work together with customers to turn their ideas into reality.

- There is no need to worry about formalities – we are patient and we know how to work from hand drawings, sketches and broken parts that need to be replaced!

- Small quantities are not a problem -- many customers need only one part.

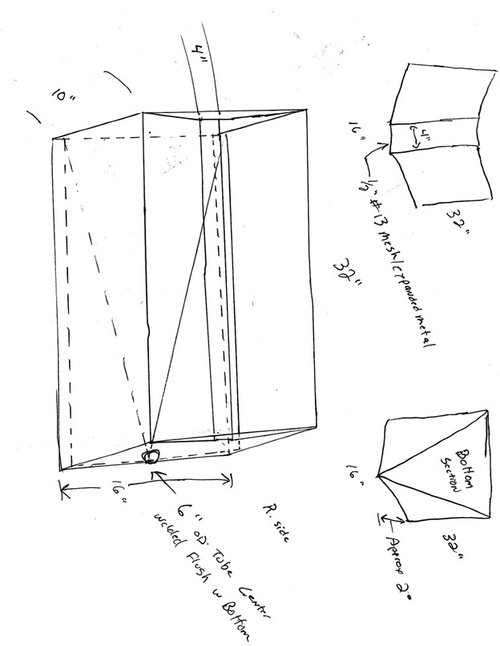

Here are a couple examples of customer sketches that we have worked from:

.jpg)

A local carpenter needed 36 brackets cut, bent and powder coated ASAP. He brought this sketch in late one afternoon and discussed his needs. We made the parts the following day.

Local shops often send sketches of parts for legacy products or equipment repairs. This is an example of a custom sheet metal box. The customer emailed this sketch and we fabricated it after a brief phone call to clarify the information.

How Long

Does It Take?

Simple parts cut from common material are often cut the same day that the print is approved and always within two business days.

Additional operations may add time.

We include a time estimate in our quotes for large quantities, complex parts and parts from material that is not stocked. We can usually get special materials in a few business days.

We Provide Immediate Services When Needed. If you have an urgent request, please call 440-214-9018 to discuss how we can help.

Artwork & Metal Signs

We receive many requests for artwork or signs that include artwork.

There are many internet sites that provide .dxf files for artwork. Experience has shown these files are often loaded with defects. We have software tools that can clean and repair many of these files. If you want artwork cut, we will attempt to use the file.

Sometimes, these files are so poor that extensive graphic design work is required to produce a cuttable result. We will advise in these cases because we cannot provide extensive editing as a free service.

Let's Get Started

Email us your Print, Sketch or CAD File — We respond promptly.