Powder coating is durable, cost-effective, and environmentally friendly.

- Our in-house process delivers consistently high-quality results.

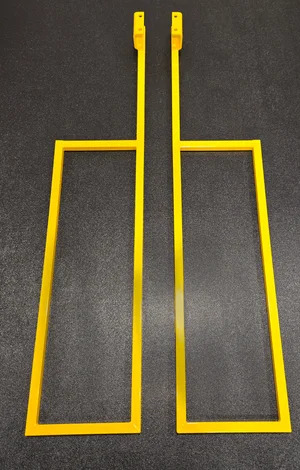

- We can powder coat all types of metals, including hot-rolled steel, cold-rolled steel, galvanized steel, and aluminum.

- We powder coat a wide range of fabricated parts.

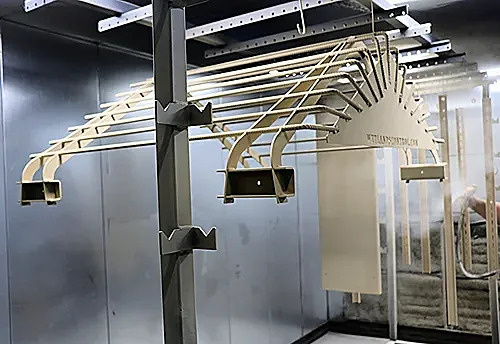

- We have a batch system with a 6 ft × 8 ft × 14 ft capacity.

- Our facility has high ceilings with overhead crane coverage to easily handle large and heavy parts.

Finish Options

Various types and finishes are available:

- Low, Medium & High Gloss

- Matte or Textured

- Special requirements

- High temperature

- Enhanced corrosion resistance

- Enhanced UV resistance

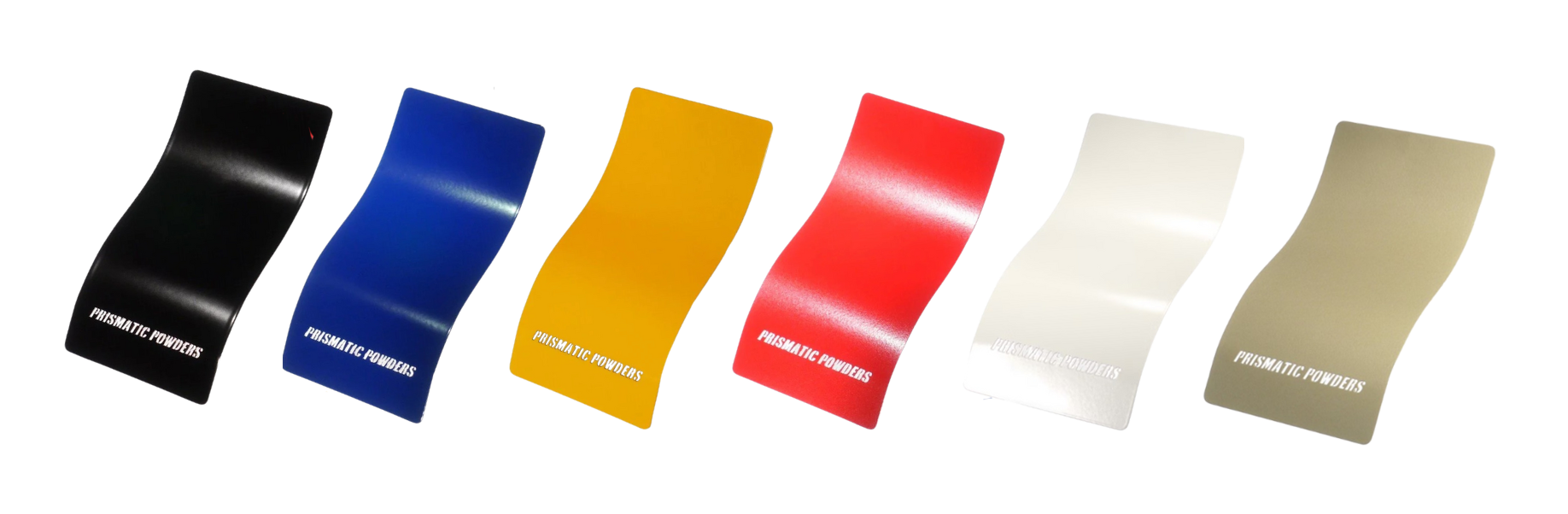

Over 6,500 colors are available

We can obtain virtually any color with a few days' notice.

We stock and spray the following colors on a regular basis:

How Do You Get

Your Part Powder Coated?

Simply indicate that you want powder coating and we will include it in the quote for your part.

Unfortunately, we do not routinely accept repair parts, wheels, ATV frames, etc. for powder coating. We are not equipped to properly clean and prepare these parts. We will coat certain items that are presented in clean condition and ready to paint. Please call us on 440-214-9018 to discuss if we can help.

How Long

Does It Take?

Powder coating typically adds 1 to 3 business days to fabricated parts.

Powder Coating Process

To achieve durable and high-quality powder coating results, we follow a precise process:

Pretreatment

Parts are thoroughly cleaned to remove contaminants, and chemical treatments are applied to ensure powder adhesion and provide protection against corrosion.

Powder Coating

We use the Gema OptiSelect® Pro SuperCorona system to get the best and most uniform application possible.

Curing

The coated parts are placed in a high-temperature curing oven to melt the powder and bond it to the metal.