3D Printing

Call UsWe utilize filament printers to visualize design concepts and to create functional rapid-prototypes, assembly fixtures, and specialized tools.

The accuracy and surface finish are excellent.

Hardware can be embedded in the parts to improve functionality.

Everybody Can 3D Print — Why Does it Matter?

Printing parts is not our business — we use printed parts to create quick and inexpensive tooling that enables us to create a lot of added value.

- Alignment fixtures

- Molds for casting resins

- Nozzles

- Special packaging

- Control plates, brackets…..

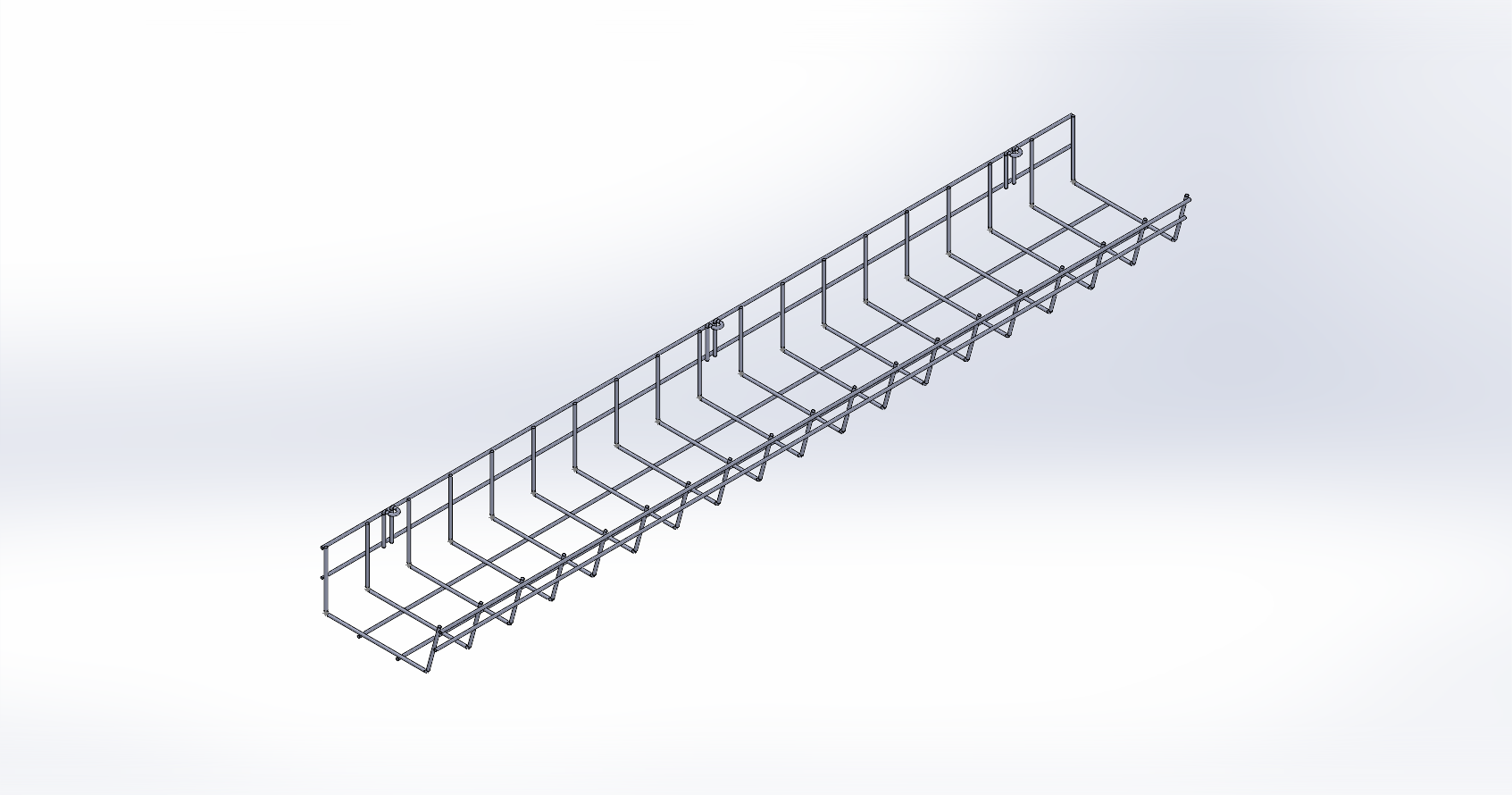

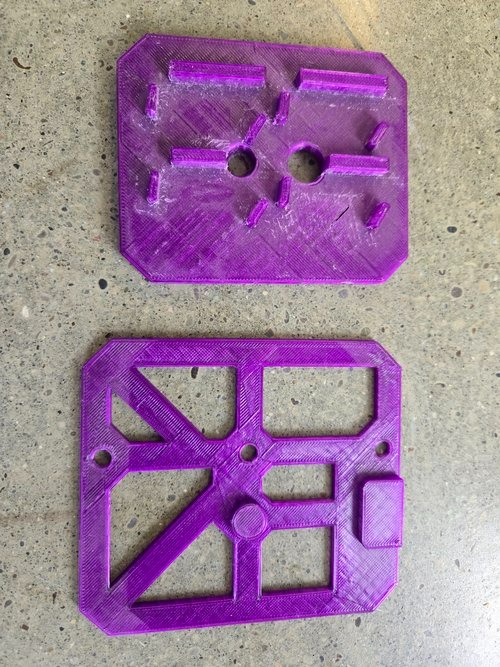

This example shows a magnetic welding fixture to make wire baskets like the one pictured. The black plastic parts are magnet holders that hold wires for welding into the basket blank. These could be machined from a plastic bar, molded from resin or 3D printed. 3D printing is faster and less expensive by far!

The fixture enables us to automate the welding which greatly lowers to product cost.

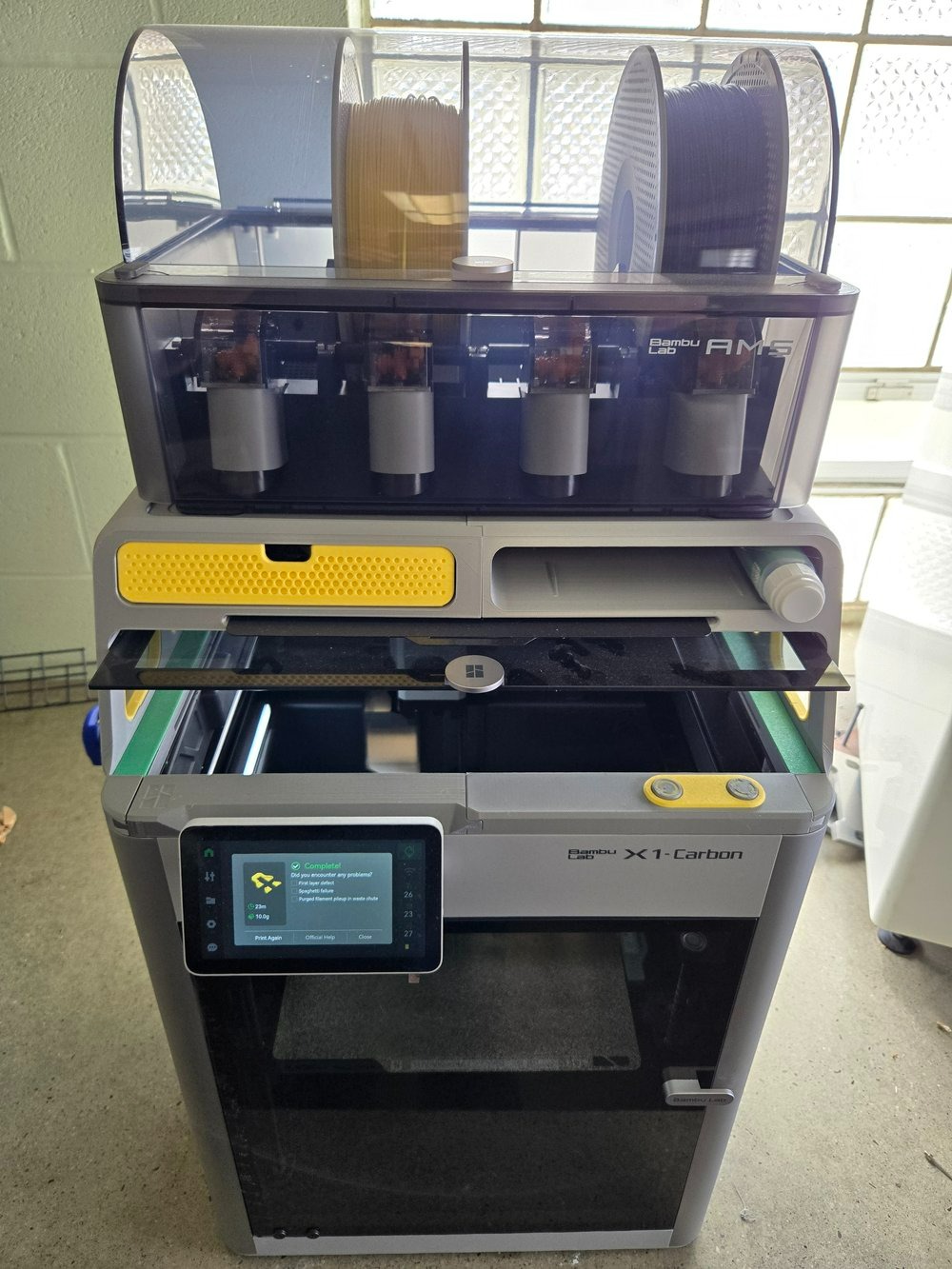

We use different filament types in a variety of colors.

- PLA – most common low cost

- ABS – added material strength

- PETG – transparent parts

- ASA – UV resistance for outdoor use

- TPU – flexible parts imitating rubber Carbon-Fiber-Reinforced – better dimensional stability

The process is simple:

A 3D CAD file is created (we use SolidWorks)

CAD outputs a STEP file for the printer to use

The printer produces the part according to the STEP file. It will pause when required for embedded hardware to be inserted. The printer automatically creates supporting structures for overhangs and hollow sections.

The parts are extracted from the supporting structures and are ready for use.

Several extrusion design concepts (background) were quickly evaluated using 3D printing before costly tooling was purchased to create the actual extrusions (foreground).

Example of the special tool with a 2-piece 3D-printed frame showing the incorporation of embedded hardware.

Example of 3D-printed fixture to position parts for an assembly operation.